Showing results 1 - 9 of 9

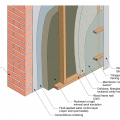

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, rigid mineral wool, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

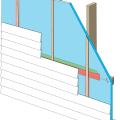

Rigid foam insulation can serve as the drainage plane when all seams are taped. Furring strips provide an air gap behind the cladding.

The “institutional” perfect wall works in all climate zones; water, air, vapor, and thermal control layers are exterior of the sheathing, assembly allows drying to interior and exterior

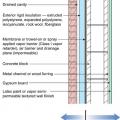

The Larsen-truss 9-inch wall cavities were covered with a smart vapor membrane that was fastened to the trusses with furring strips, which also provide an air gap behind the wood siding; each truss cavity is then filled with blown cellulose.

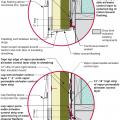

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated irregular foundation wall

Vapor-permeable mineral wool insulation is installed on the exterior side of the sill beam during an exterior wall retrofit to allow the sill beam to dry to the outside

Walls in cold climates with a Class 3 vapor retarder (latex paint) and a vapor-open continuous insulation like mineral wool allow drying to the interior or the exterior

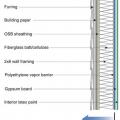

Walls in cold climates with a polyethylene vapor barrier interior of the wall cavity should have either no exterior insulation or a vapor-open continuous insulation like mineral wool that allows drying to the exterior