Showing results 101 - 133 of 133

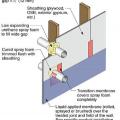

Two layers of XPS are installed with staggered seams over a liquid-applied membrane on the structural sheathing

Unfaced fiberglass batt insulation is installed to completely fill the wall cavities and is sliced to fit around wiring, piping, and other obstructions in the wall cavities

Use flashing tape to seal around any pipes or vents that penetrate through the foam

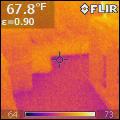

Wrong – A visible gap in the insulated sheathing introduces unwanted outside air, creating a thermal bypass and encouraging convective air flow

Wrong – Compression and misalignment because insulation is not split around plumbing

Wrong – Compression and misalignment because insulation is not split around wires

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen

Wrong – Either this tape was not pressed down firmly or the surface was wet or dirty so the tape is not sticking properly even during construction.

Wrong – If the insulated sheathing will serve as an air barrier and drainage plane, any cuts and seams must be taped or sealed.

Wrong – No blocking installed to prevent attic insulation from falling into stairs and opening

Wrong – The backing on this knee wall was not air sealed prior to adding insulation.

Wrong – The batt insulation on this knee wall is not properly supported and there is no air sealed rigid backing to provide a solid air barrier.

Wrong – The framing and wind baffle installation will not allow for required insulation depth.

Wrong – When insulated sheathing is installed correctly, you should not see daylight. Nail holes were also left unplugged.