Showing results 1 - 37 of 37

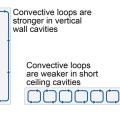

Airflow within drop-in ceiling assemblies is generally not a concern due to the limited vertical height. However, airflow within air gaps in walls is a concern due to the much larger vertical height.

A paint-on waterproofing covers the exterior and tops of the concrete block foundation walls and piers to block moisture moving up through the concrete, while foil-faced R-13 insulation lines the inside surface of the exterior walls.

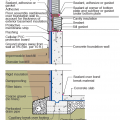

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

Exterior fiberglass insulation on this new home was (incorrectly) cut to terminate below-grade after backfill, which will expose the above-grade portions of the foundation wall to cold temperatures

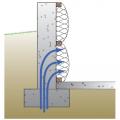

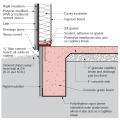

Exterior XPS basement insulation is correctly installed to completely cover the foundation wall

Foil-faced rigid foam and spray foam can be used to insulate a basement on the interior; use good moisture management techniques to keep the basement dry

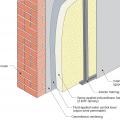

Masonry wall interior retrofit with fluid-applied water control layer and wood-framed wall with cavity insulation (climate zones 1-4 only)

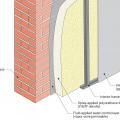

Masonry wall interior retrofit with fluid-applied water control layer, mineral wool rigid foam, and wood or metal stud service cavity (climate zones 1-4 only)

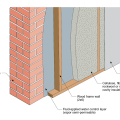

Masonry wall interior retrofit with fluid-applied water control layer, spray foam, and wood or metal stud service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, mineral wool rigid foam, and wood or metal stud service cavity (climate zones 1-4 only)

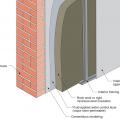

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, rigid mineral wool, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, spray foam, and wood or metal stud service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

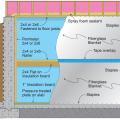

Moisture can migrate from below the foundation to the basement wall and insulation cavity in a conventional blanket insulation installation

Moisture-resistant rigid foam insulation was installed to provide a continuous air and thermal barrier behind the tub-shower insert.

On top of the ice-and-water shield, the builder installed horizontal beams that were raised 6 inches off the deck to allow room for spray foam insulation.

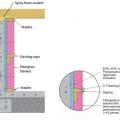

R-5 XPS rigid foam exterior sheathing provides an air seal, moisture barrier, and additional insulation value.

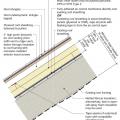

Retrofit an existing roof by installing rigid foam above the roof deck with a ventilation space between the rigid foam and the new roof sheathing plus new moisture and air control layers and cavity insulation in the roof rafters.

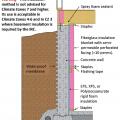

Right - A continuous layer of rigid foam insulation is installed against the foundation, and the perforated fiberglass insulation blanket is installed over that and covered with a semipermeable facing.

Right - Reduce condensation risks to blanket insulation by installing perforated vapor retarder covered fiberglass blankets over rigid foam that is air-sealed at all edges; staple the blanket to nailers and top/bottom plates and tape over the seams.

Right - Section view showing how to air-seal and insulate a basement wall with perforated blanket insulation by installing it over air-sealed rigid insulation board to reduce condensation risk in the fiberglass blanket.

Right - This concrete basement wall has exterior rigid insulation and comprehensive moisture management details.

Right – The air- and water-barrier material lining the shower stall is mastic sealed to prevent leakage and rigid foam insulation is installed on the floor of the shower.

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

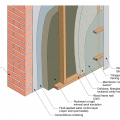

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

The builder in this very cold climate installed three layers of unfaced mineral wool batt in the double wall with a code-required vapor barrier between the middle and inner layers of wall insulation that is taped to barriers in the ceiling and floor.

The builder installed 1.5 inches of soy-based spray foam on the outside of the walls over the OSB sheathing, then kept a ¾ inch gap between the foam and the brick veneer siding to allow moisture vapor from the bricks to dissipate.

The builder laid down a 4-inch base of aggregate rock, then covered that with a plastic vapor barrier that is taped at all seams and around all penetrations before installing the rigid foam under-slab insulation.

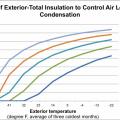

To reduce the risk of condensation on the interior of the roof sheathing in cold weather, the ratio of exterior (above-deck) insulation must be increased as a percent of total attic insulation as outside temperature decreases

When architects and builders think of the house as a systems, all of the parts are designed to work together for a healthy, durable home that minimizes builder callbacks while cutting energy, maintenance, and repair costs down the road.

When condensation forms on the interior side of wall sheathing and is not able to dry out, it can lead to mold growth and rotting of wall sheathing and framing

Wrong - Air leakage from the conditioned space to the basement foundation wall can lead to condensation or moisture issues in a conventional blanket insulation installation.

Wrong - Moisture from within the basement foundation wall can migrate into the insulation cavity in a conventional blanket insulation installation.

Wrong - Plastic-covered blanket insulation that is installed directly against concrete walls with no rigid foam or closed-cell spray foam covering the concrete could trap moisture coming through the concrete, leading to mold, moisture, and odor problems.

Wrong – A clothes dryer that vents to the crawlspace can contribute moisture to the crawlspace; this can result in damp, molding, and rotting insulation

Wrong – Don’t use nails to fasten poly vapor barrier around flex ducts; it will allow moist air to reach the ducts where it could condense and ruin the insulation.

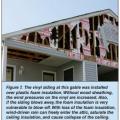

Wrong – The gable end wall failed because the rigid foam sheathing was not backed up by plywood or OSB.