Showing results 1 - 24 of 24

Concrete is being poured into the wall forms made by the rigid foam insulated concrete form blocks.

Concrete is poured into the rigid foam shell of the insulated concrete form (ICF) walls; a plastic water barrier has already been installed to protect the below-grade wall surfaces.

Construct exterior walls with insulated concrete forms (ICFs) that provide insulation without thermal bridging, as well as air sealing, a drainage plane, and high structural strength.

ICFs provide continuous wall insulation from the roof to the footing with very little thermal bridging

Manatee County Habitat for Humanity trains its volunteers to construct homes made of construct insulated concrete forms (ICFs).

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

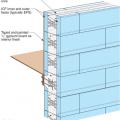

Seams in the ICF block are sealed so the EPS foam surface can serve as the drainage plane; no house wrap is needed.

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

The Habitat affiliate makes its own “ICF” foundation walls with rigid foam held in place with wood spacers.

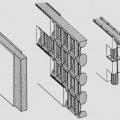

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

This community of production homes in central New York state was built with insulated concrete forms (ICFs), which provide a highly insulated, airtight structure that is fire-, pest-, wind-, and earthquake-resistant.

Three common ICF wall systems: the flat wall, the waffle wall, and the post-and-beam wall

Utilities are commonly recessed into cutouts in the foam after concrete has been poured

Window and door rough openings in the ICF wall are surrounded with pressure-treated wood

Wiring runs are covered with canned spray foam to maintain the continuous foam layer that covers the inside and outside of these ICF block walls.