Showing results 1 - 43 of 43

A nylon draw band and tensioning tool are used to secure the inner coil of the pre-insulated flexible duct

A nylon draw band and tensioning tool are used to secure the inner liner of the pre-insulated flexible duct

After securing the inner coil, cover the draw band and the seam with a generous amount of mastic

Air seal and insulate flex ducts

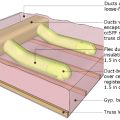

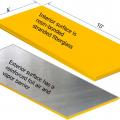

All other supply ducts and all return ducts in unconditioned space have insulation ≥ R-6

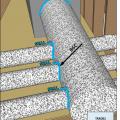

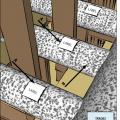

Baffles are installed to protect airflow from the soffits to the ridge vents before the ceiling drywall and attic insulation are installed.

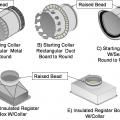

Collars that are specifically made for flexible duct have a raised bead to prevent the duct from slipping off

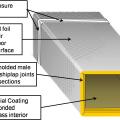

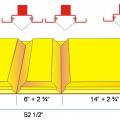

Cut fiber board with a red V-groove tool and a gray shiplap tool to create mitered corners and a shiplapped edge for duct sections

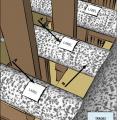

Ducts are insulated but strapping is compressing the insulation therefore reducing the R-value

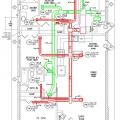

Example of an HVAC installer’s balancing report form

Hand tools for cutting fiber board sheets include a knife, straight edge, and color-coded edge-cutting tools

Prescriptive Path: Supply ducts in unconditioned attic have insulation ≥ R-8. Performance Path: Supply ducts in unconditioned attic have insulation ≥ R-6

Pull the insulation and outer liner of the flex duct over the collar to come in full contact with the liner and insulation of the trunk line or fitting and tape in place

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

Right – An insulated space is provided in the home’s attic to house the HVAC equipment.

Right – R-25 of open-cell spray foam lines this new home’s attic ceiling, to protect HVAC ducts from heat and cold.

Right – Rigid foam is installed behind HVAC ducts to provide additional insulation to the ducts which are installed within the conditioned space.

Right – Spray foam air seals and insulates the walls including the walls behind the fireplace and covers the underside of the roof deck of this mixed-dry climate home to provide an insulated attic space for HVAC ducts.

Seal all joints and seams in the metal ductwork with mastic before installing insulation

Seal seams in fiber board ducts with out-clinching staples, UL-181A-approved tape, and mastic

The tape is covered with mastic to ensure an airtight seal between the duct and the fitting

To attach the flex duct to a main trunk duct or any other connection, the flex duct is pulled over the connecting collar at least 2 inches past the raised bead, then the insulation is pulled back

Trunk to duct connections are properly insulated and have been sealed with mastic

Two pieces of flex duct are spliced together with a metal sleeve, nylon draw bands, mastic, metal tape, and more mastic

When architects and builders think of the house as a systems, all of the parts are designed to work together for a healthy, durable home that minimizes builder callbacks while cutting energy, maintenance, and repair costs down the road.

When wrapping metal ducts with insulation allow two inches of overlap and staple along the seam with outward clinching staples

Wrong- A tie strap should not be used over the duct outer liner because it can compress the insulation. Tuck in the fibrous insulation and seal the outer liner to the connecting duct with mastic or foil tape (Steven Winter Associates 2013).