Showing results 201 - 250 of 354

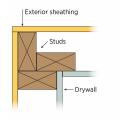

Right – Wood-to-sheathing joints are caulked so the sheathing can provide an air barrier for the home.

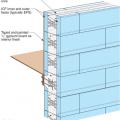

Right- This concrete block home in the hot-humid climate is insulated on the interior with rigid EPS foam; all framing uses mold- and termite-resistant borate-treated lumber.

Right- This house uses CMU construction for flood and termite resistance as well as thermal mass

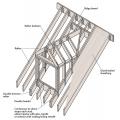

Roof dormer is braced with steel connectors and strapping to increase its resistance to uplift

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

Single framed wall converted to double wall and insulated with closed-cell spray foam

Solid wood blocking was installed in the walls to accommodate future grab bars in both bathrooms.

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

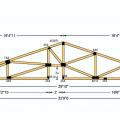

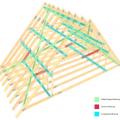

Specially designed roof trusses come with a two-foot by two-foot notch cut next to the center post providing space to install an insulated duct chase inside the home’s conditioned space but above the normal ceiling height.

Spray foam adhesive provides an extra water resistant layer to the joints and seams on the inside of attics.

Sprayer-applied sealant seals every seam in the sheathing and framing of this double-walled home.

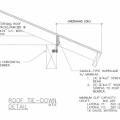

Strengthen an existing roof by applying two-part spray-applied polyurethane foam adhesive to all sheathing and framing joints from the underside of the roof

Structural insulated panels offer a continuous layer of thermal protection and draft resistance around the home and come from the factory precut for fast assembly.

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

The 2x4 wall studs are staggered along the 2x6 sill plate providing space to weave insulation around each stud to stop thermal bridging through the wall.

The advance-framed 2x6 24-inch on-center walls are covered with netting then filled with R-23 blown fiberglass.

The attic is sealed and insulated along the underside of the roof deck with 5.5 inches of polyurethane spray foam, providing conditioned space for the HVAC system.

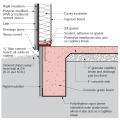

The basement walls’ interior framing is set in 3 inches from the concrete to allow space for closed-cell foam that is sprayed directly on the concrete, then blown cellulose is added to fill the wall cavity.

The builder staggers 2x4 studs on 2x6 top and bottom plates which provides gaps to fill in insulation around the framing for a continuous blanket of insulation.

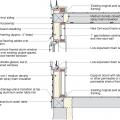

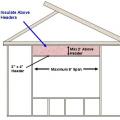

The components of a framed wall include from inside to out: gypsum, wood studs, OSB or plywood sheathing, and siding.

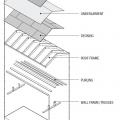

The components of a roof include the rafter framing or trusses, purlins, plywood roof decking, underlayment, and the roof covering.

The double walls form a 12-inch cavity that was sheathed with a coated OSB then coated with 3 inches of closed-cell spray foam; they will be filled with 9 inches of blown fiberglass.

The drywall above the dropped ceiling duct chase extends beyond adjoining top plates for a continuous air barrier

The energy-saving double wall construction uses two side-by-side stud walls, providing an extra-thick wall cavity that can be filled with more than twice as much insulation as a 2x6 wall.

The exterior walls are double walls consisting of two 2x4 stud walls set 3 inches apart to form a 10-inch-thick wall cavity that is filled with blown-in fiberglass to provide a continuous R-40 blanket of insulation around the home.

The exterior walls of this home consist of two wall cavities: a 2x6 wall with plywood sheathing plus 8-inch I-joists sheathed with engineered wood; both cavities are dense-packed with cellulose for R-60 total.

The highly efficient double wall system consists of two sets of stud walls set side by side to create a 12-inch-thick double-stud wall cavity that is filled with a continuous blanket of R-44 dense-packed cellulose insulation.

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

The improved three-stud corner allows insulation to be installed later, in sequence

The main trunk line of the ducts runs within an insulated duct chase installed in a notch designed into the roof trusses that runs the length of the home to provide supply air directly to most of the home’s ceiling registers.

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The open-web roof and floor joists, laminated beams, and I-beams reduce raw lumber use and increase load-bearing capacity, while resisting shrinking, twisting, splitting, and warping.

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The rim joists and top plates are air sealed and insulated with open-cell spray foam while the walls are filled with blown fiberglass.

The roof trusses and all other framing in this hot-humid climate home is treated with borate for mold and termite resistance.

The seams in the plywood are taped seams in the cathedral ceiling serve as part of the advanced home sealing strategy.

Thermal and air barriers at rim joist or new blocking prevent Infiltration of unconditioned air into the floor cavity

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall