Showing results 51 - 100 of 354

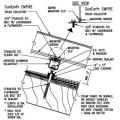

Critical connections for providing a continuous load path in buildings and storm shelters

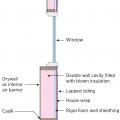

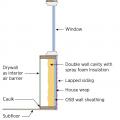

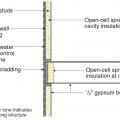

Drywall was removed and the existing 2x4 walls were filled with 3.5 inches of dense-packed cellulose. Outside, the ½-inch plywood was topped with house wrap, 1.5 inches closed-cell rigid foam, 1x3 furring strips, and fiber cement siding.

Each floor of this two-story modular home is constructed in a factory, including the 2x6, 24-inch on-center walls, R-21 fiberglass batt cavity insulation, and rigid exterior foam, housewrap, windows, and trim, then connected on site.

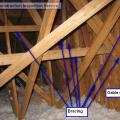

End wall failure under hurricane force winds due to inadequate bracing of the gable end wall.

Engineered studs of wood mixed with resin provide very straight, strong studs for the 2x6 walls.

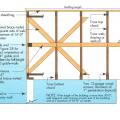

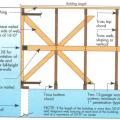

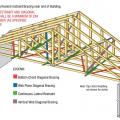

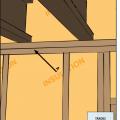

Example A of a gable truss and gable end wall bracing for a home in a hurricane region

Example B of a gable truss and gable end wall bracing for a home in a hurricane region

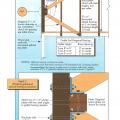

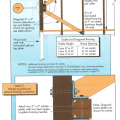

Example of a truss bracing requirement tag that some truss manufactures place strategically onto the truss to remind installers

Example truss bracing for resisting wind loads as determined by design software used by truss manufactures

Fill in the hole left by the missing top plate with a rigid air blocking material or rolled batt insulation that is spray foamed in place

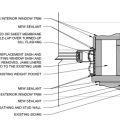

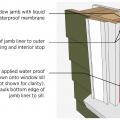

Framing is built around the window before exterior rigid foam is installed on the exterior walls around the window.

Gaps at shared common walls can be a significant source of air leakage in multi-family buildings

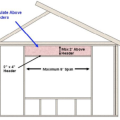

Headers over windows on non-load-bearing walls are open to allow room for insulation.

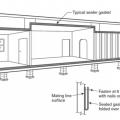

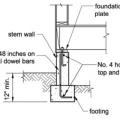

How to properly anchor a new home to its foundation with foundation sill plate, stem wall, and footing

ICF bricks are stacked to form hollow walls that are reinforced with steel rebar before the concrete is poured in

ICFs provide continuous wall insulation from the roof to the footing with very little thermal bridging

Improper continuous load path design lacking bracing results in the failure of gable end walls under high wind conditions.

In areas prone to high winds and hurricanes, double vertical “jack trim” and horizontal “header” and “sill” studs are recommended on all sides of window and door openings.

In high-wind regions, special hardware is used for most framing connections; toe-nailing is not acceptable.

Install continuous top plates or blocking at the tops of walls adjacent to conditioned space to minimize air leakage.

Installing ladder blocking at interior-exterior wall intersections rather than three solid studs in the exterior wall as the supporting surface allows room for insulation in the exterior wall.

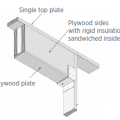

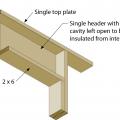

Instead of solid timber headers over windows, insulated headers can be used consisting of prefabricated structural insulated panels or site-fabricated with two sheets of plywood sandwiching a layer of rigid foam.

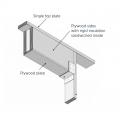

Instead of solid timber headers over windows, the headers can be insulated by using a sheet of plywood or one piece of solid timer on the exterior with a layer of insulation to the inside.

Insulated header made of one piece of plywood aligned with exterior wall, with room for insulation to inside

Insulated header made of two pieces of plywood that sandwich a layer of rigid foam insulation

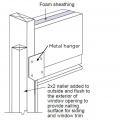

Insulated headers can be hung with metal hangers instead of jack studs to reduce lumber usage

Insulating sheathing is extended up to the roof rafters and sealed around the framing with spray foam as part of this exterior wall retrofit