Showing results 1 - 100 of 354

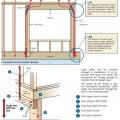

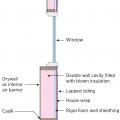

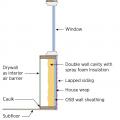

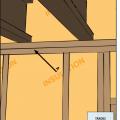

Example of the advanced framing technique, double-stud wall cavity, which will later be filled with blown insulation

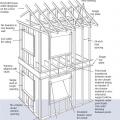

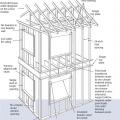

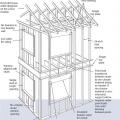

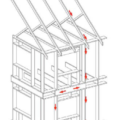

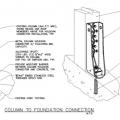

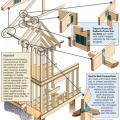

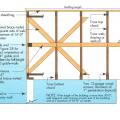

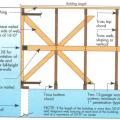

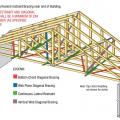

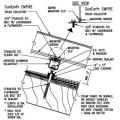

A continuous load path uses structural connections to transfer horizontal and vertical loads from the roof to the foundation to help keep the building intact in high-wind and seismic events

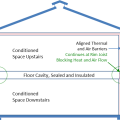

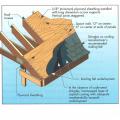

A floor cavity between the first and second floor can provide a conditioned space for HVAC ducts if the rim joists are insulated and air sealed, if sufficient space is available, and if open-web floor joists are used

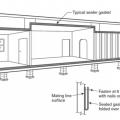

A foam gasket is installed along the top plates before installing drywall as an air-sealing step to help achieve a quieter, draft-free home.

A large bead of caulk is installed on the interior surface of the wall top and bottom plates to provide an air sealing gasket between the framing and the dry wall.

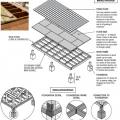

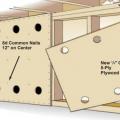

A layer of rigid foam is sandwiched between two layers of 2x8 lumber in this insulated header over a window.

A raised wood pier foundation can raise the subfloor above the design flood elevation.

A water heater is anchored to 2 x 4 wood blocking that is attached to the wall studs.

Add metal connectors to strengthen framing connections in an existing wall from inside the home by removing drywall.

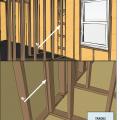

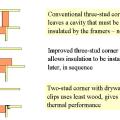

Advanced framing details include corners that are constructed with fewer studs or studs aligned so that insulation can be installed in the corner.

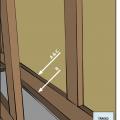

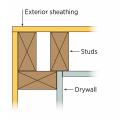

Advanced framing details include framing aligned to allow for insulation at interior-exterior wall intersections.

Advanced framing details include open headers and reduced framing around windows and two-stud corners to allow more room for insulation in the wall cavities while reducing lumber costs.

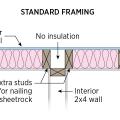

Advanced framing details include using the minimum amount of wall studs permitted by code.

Advanced framing details throughout house limit use of lumber and makes space for bonus insulation.

Advanced framing techniques include constructing on a 2-foot grid where wall studs are placed 24 inches on center and aligned with roof and floor trusses for a continuous load path from roof to foundation.

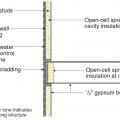

Advanced framing techniques including 2x6 walls spaced at 24 inches on center and ladder blocking at wall intersections allow more space for insulation in the wall cavities while open-web floor joists provide space between floors for ducting.

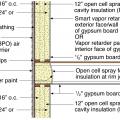

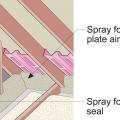

After spraying the 2x6 wall cavities with 2 inches (R-13) of closed-cell spray foam, the walls are covered with netting and an additional 3.5 inches of fiberglass (R-13) is blown in.

Air seal and insulate double-walls that are half-height or full-height walls used as architectural features in homes.

Air seal the common wall between units in a multifamily structure to minimize air leakage.

An indoor water heater should be secured to the wall’s studs to prevent it from moving or tipping over in the event of an earthquake

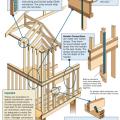

Angle support framing is added to brace a long gable overhang constructed using the ladder framing method.

Attach the interior 2x4 wall to the exterior wall top plate with a flat metal connector plate

Baffles will keep insulation out of the soffit vents and wind out of the insulation in this vented attic.

Balloon-framed walls have no top plate to prevent air flow into wall cavity

Before installing drywall, contractors install two beads of a sprayer-applied elastomeric sealant along framing and top plates to forma a flexible, air-tight seal between the framing and dry wall.

Bolted metal hurricane strapping ties the roofing to the framing and the framing to the foundation walls for resistance to high winds.

Braced cripple wall construction in crawlspace anchored to framing and foundation

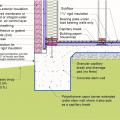

Brick veneer framed wall supported by a concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

Closed-cell spray foam insulation is added to the wall cavities of an existing exterior wall

Composition shingle roofing system showing sheathing and hot-mopped underlayment

Connecting hardware helps tie the roof to the walls to ensure a continuous load path to improve a building’s resistance to high winds, floods, and earthquakes.

Connecting hardware helps tie the walls to the top plates and rim joists to ensure a continuous load path to improve a building’s resistance to high winds, floods, and earthquakes.

Construct a double wall consisting of two framed walls forming a wide wall cavity for more insulation in the home’s exterior walls.

Conventional three-stud corner leaves a cavity that must be insulated by the framers—not good.

Conventional three-stud corners leave a cavity that must be insulated by the framers—not good

Critical connections for providing a continuous load path in buildings and storm shelters

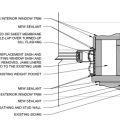

Drywall was removed and the existing 2x4 walls were filled with 3.5 inches of dense-packed cellulose. Outside, the ½-inch plywood was topped with house wrap, 1.5 inches closed-cell rigid foam, 1x3 furring strips, and fiber cement siding.

Each floor of this two-story modular home is constructed in a factory, including the 2x6, 24-inch on-center walls, R-21 fiberglass batt cavity insulation, and rigid exterior foam, housewrap, windows, and trim, then connected on site.

End wall failure under hurricane force winds due to inadequate bracing of the gable end wall.

Engineered studs of wood mixed with resin provide very straight, strong studs for the 2x6 walls.

Example A of a gable truss and gable end wall bracing for a home in a hurricane region

Example B of a gable truss and gable end wall bracing for a home in a hurricane region

Example of a truss bracing requirement tag that some truss manufactures place strategically onto the truss to remind installers

Example truss bracing for resisting wind loads as determined by design software used by truss manufactures

Fill in the hole left by the missing top plate with a rigid air blocking material or rolled batt insulation that is spray foamed in place

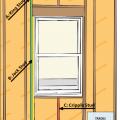

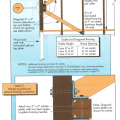

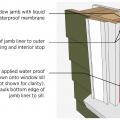

Framing is built around the window before exterior rigid foam is installed on the exterior walls around the window.

Gaps at shared common walls can be a significant source of air leakage in multi-family buildings

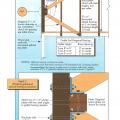

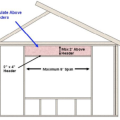

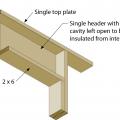

Headers over windows on non-load-bearing walls are open to allow room for insulation.

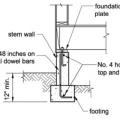

How to properly anchor a new home to its foundation with foundation sill plate, stem wall, and footing

ICF bricks are stacked to form hollow walls that are reinforced with steel rebar before the concrete is poured in

ICFs provide continuous wall insulation from the roof to the footing with very little thermal bridging

Improper continuous load path design lacking bracing results in the failure of gable end walls under high wind conditions.

In areas prone to high winds and hurricanes, double vertical “jack trim” and horizontal “header” and “sill” studs are recommended on all sides of window and door openings.

In high-wind regions, special hardware is used for most framing connections; toe-nailing is not acceptable.

Install continuous top plates or blocking at the tops of walls adjacent to conditioned space to minimize air leakage.

Installing ladder blocking at interior-exterior wall intersections rather than three solid studs in the exterior wall as the supporting surface allows room for insulation in the exterior wall.

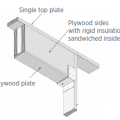

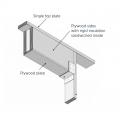

Instead of solid timber headers over windows, insulated headers can be used consisting of prefabricated structural insulated panels or site-fabricated with two sheets of plywood sandwiching a layer of rigid foam.

Instead of solid timber headers over windows, the headers can be insulated by using a sheet of plywood or one piece of solid timer on the exterior with a layer of insulation to the inside.

Insulated header made of one piece of plywood aligned with exterior wall, with room for insulation to inside

Insulated header made of two pieces of plywood that sandwich a layer of rigid foam insulation

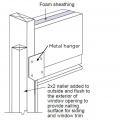

Insulated headers can be hung with metal hangers instead of jack studs to reduce lumber usage

Insulating sheathing is extended up to the roof rafters and sealed around the framing with spray foam as part of this exterior wall retrofit