Showing results 351 - 400 of 559

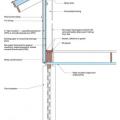

Right – Interior grade is elevated and flood vents are located slightly above interior grade

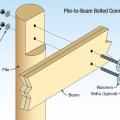

Right – Notch cut into pile takes less than 50% of cross section, cut is treated with wood preservative, and beam is installed with corrosion-resistant bolts.

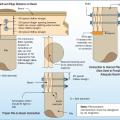

Right – Polyethylene sheeting completely covers the aggregate and the footing with no tears or open seams

Right – Polyethylene sheeting is laid over aggregate and over footing to provide a capillary break between the ground and the slab and between the footing and the stem wall

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – Prepoured foundation panels with integrated insulation and vapor barrier are installed in place.

Right – R-20 of XPS and polyiso rigid foam were added on the slab shelf that is part of this precast foundation wall system.

Right – Rain barrel installed with an overflow spout terminating at least 5 feet from foundation

Right – Rigid foam was attached to the tops of the precast foundation walls to form an insulated edge for the floor slab.

Right – Spray foam insulation was sprayed onto the ground and along the sides of the foundation walls and piers of this insulated crawl space.

Right – The drain slopes away from the foundation and terminates at the proper distance

Right – The drain tile connects to a sump pump which will pump water away from the foundation

Right – The drain tile is installed along the bottom of the entire foundation footing

Right – The drain tile is wrapped in fabric which will prevent it clogging with debris

Right – The entire first floor and second floor of these modular homes were assembled in the factory and installed on an insulated concrete basement foundation on site.

Right – The floor and wall system on this open-foundation home use rigid foam rather than fibrous cavity insulation to reduce risk of water damage.

Right – The foundation of this ICF home was constructed of ICFs that were set in place on a gravel bed, then 3.5 inches (R-36) of closed-cell spray foam was sprayed directly onto the gravel, providing an effective air, vapor, and thermal barrier.

Right – The foundation wall consists of prefab concrete wall panels with integrated insulation.

Right – The insulated concrete forms that are below-grade have a damp-proof coating to prevent moisture seeping into the foundation

Right – The joint between the foundation wall and the mud sill is thoroughly sealed with a liquid-applied sealant.

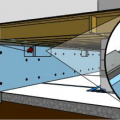

Right – The latticework between columns in this raised foundation will allow free flow of water in the event of a flood

Right – The raised slab foundation has a 3-ft stem wall of filled concrete block, then is back-filled with compacted dirt and crushed rock, then insulated with 1” rigid foam covered with taped vapor barrier, under a floor slab.

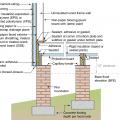

Right – The raised-slab, brick-and-block stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The raised-slab, CMU block stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The raised-slab, poured-concrete stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The seam between the slab and the foundation wall is sealed with urethane caulk.

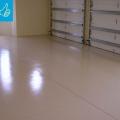

Right – The slab is coated with two coats of epoxy paint to minimize moisture transfer through the slab from the ground.

Right – This column foundation has no HVAC equipment, piping, electrical components, or structural walls below the elevated floor system

Right – This crawlspace window was completely sealed off on the inside and outside with air barrier and water-proof materials and the window well was filled in to an above-grade height to prevent bulk water from entering the crawlspace

Right – This floor system on a column foundation is insulated using closed-cell spray foam rather than fibrous insulation

Right – This wall is constructed with the sill plate overhanging the top of the foundation wall so that when rigid foam is installed on the exterior of the foundation wall, its surface will align with the surface of the wall sheathing.

Right – Two inches of rigid foam was installed on the ground before pouring the basement floor slab while precast, pre-insulated concrete panels comprise the basement walls.

Right – Walls, windows, and wiring are installed in the factory for these modular homes, which are installed at the site on basement foundations made of insulated concrete wall panels.

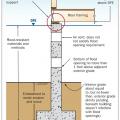

Right-Flood resistant foundation walls lift the floor framing above the DFE and include flood openings to let flood waters pass through.

Right-Polyethylene sheeting is correctly installed over aggregate and taped to pillars and foundation wall

Rigid foam extends under the full slab and lines the inside edges of the foundation walls.

Rigid foam insulation and a thin slab were installed over the dirt and gravel of this sealed crawlspace

Rigid foam provides the code-required insulation values for this floor and wall assembly so that fibrous cavity insulation can be avoided, reducing risk of floodwater damage

Rigid insulation and air-sealing can be used to thermally isolate garages from multifamily row houses/town houses with basement foundations in IECC Climate Zones 3 or higher.