Showing results 251 - 500 of 504

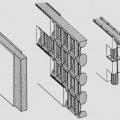

Right – Rigid air barrier installed between double-wall assembly. Inside cavity will be insulated

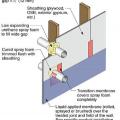

Right – Spray foam was installed at the sheathing intersection as well as the sill plate to sub-floor connection.

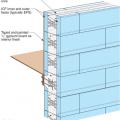

Right – Structural insulated sheathing can provide racking strength (lateral load resistance), and serve as an air barrier and thermal barrier if installed according to manufacturer’s specifications with taped, sealed seams

Right – The blower door is installed snugly and securely to the door frame during testing

Right – The blower door pressure reference hose is placed well away from the outdoor side of the fan

Right – The rim joists above the pre-insulated basement walls are sealed and insulated with spray foam to prevent air leakage at this juncture in the building envelope.

Right – The rough opening around the window has been filled with low-expansion foam to air seal.

Right – The rough opening around window has been filled with backer-rod to air seal.

Right – The sill plate was sprayed with foam prior to installation atop foundation.

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right – This ICAT recessed light is sprayed with foam to act as gasket against the drywall.

Right – Weatherstripping has been installed and remains in contact when the door is closed.

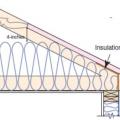

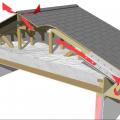

Right – Wind baffle installation maintains necessary code clearance between baffle and roof deck

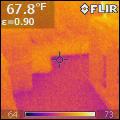

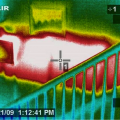

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

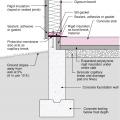

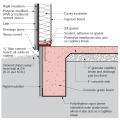

Rigid foam forms an insulating bond break between the foundation wall and the slab

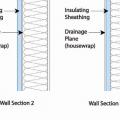

Rigid foam insulated sheathing placed exterior to house wrap, interior to house wrap, or take the place of the house wrap

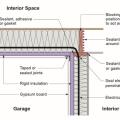

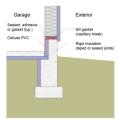

Rigid insulation and air-sealing can be used to thermally isolate garages from interior occupied space in multifamily row houses/townhouses.

Rigid insulation and air-sealing can be used to thermally isolate garages from multifamily row houses/town houses with basement foundations in IECC Climate Zones 3 or higher.

Rigid insulation can be used as a thermal break between a garage slab with a heated plenum space and a separately cast garage slab without a heated plenum space.

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

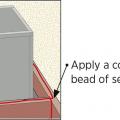

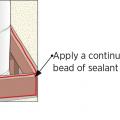

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant along top edge of chase framing

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant on top edge of chase framing

Siding has been removed so cellulose insulation can be dense-packed into the exterior walls of this home

Single framed wall converted to double wall and insulated with closed-cell spray foam

Single framed wall converted to double wall and insulated with closed-cell spray foam and loose-fill fibrous insulation

Single framed wall converted to double wall and insulated with open-cell spray foam

SIP panel walls are less susceptible to air leakage and convection issues than stick-built walls

SIP panels should be stacked high, dry, and flat

Smoke generators are used to identify air leakage sites during depressurization testing

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

Spray foam insulation is installed in open wall cavities to air seal and insulate

Spray foam provides a critical seal between the subfloor, rim joist, and sill plate

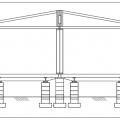

Standard roof trusses are narrow at the eaves, preventing full insulation coverage over the top plate of the exterior walls

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

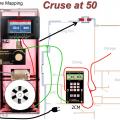

The air tightness of the garage-to-house air barrier can be tested with a blower door kit and two manometers

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The back dam of the window sill will force water out

The floor cavities under this attic kneewall are completely open to the unconditioned attic space and a prime target for wind washing

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

The individual exhaust systems for each dwelling unit in this multifamily building result in large numbers of penetrations in the exterior façade

The soffit dam and baffle allow air to flow through the vents without disturbing the insulation covering the top plates

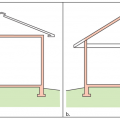

The thermal boundary for a gable roof can be located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

The wall behind the fireplace is an exterior wall and requires a thermal barrier that is continuous with the rest of the wall’s insulation

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

Thermally isolate heated garages in multifamily buildings from ambient space, and thermally isolate all garages in multifamily buildings from interior occupied space. This parking garage is thermally isolated from space above with spray foam insulation.

This assembly can be used to thermally isolate heated or partially heated garages with slab foundations from the exterior in multifamily row houses/townhouses in IECC Climate Zones 3 and higher.

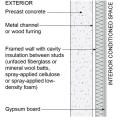

This assembly for above-grade and below-grade garage walls in any climate zone uses continuous rigid insulation along the interior of the wall.

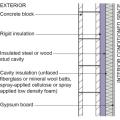

This assembly for above-grade or below-grade garage walls in any climate zone uses a hybrid of continuous rigid insulation and cavity insulation on the interior side of the wall.

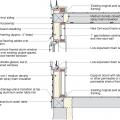

This foundation/floor/SIP wall detail shows recommended support of SIP wall panel at the sill plate

This heated garage plenum is insulated along the bottom and sides, and the insulation is fully aligned with an air barrier. The insulation at the bottom of the plenum space meets IECC insulation requirements.

This heated garage plenum space is insulated along its top, bottom and sides, and the insulation at the top of the plenum meets IECC requirements. The insulation along the top and sides is fully aligned with an air barrier.

This HRV, installed in a conditioned attic, provides balanced ventilation to the whole home

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

This technique for installing electrical wiring avoids the need to cut into the SIP panel

This wall assembly for above-grade garage walls uses cavity insulation and should only be used in IECC Climate Zones 4 or lower due to the risk of condensation on the interior surface of the concrete wall.

Three common ICF wall systems: the flat wall, the waffle wall, and the post-and-beam wall

Two layers of high-permeability house wrap are installed to provide a drainage layer between the SIPS and the homes external cladding

Two layers of XPS are installed with staggered seams over a liquid-applied membrane on the structural sheathing

Typical installation of a double section modular home on a pier and ground anchor foundation

Unfaced fiberglass batt insulation is installed to completely fill the wall cavities and is sliced to fit around wiring, piping, and other obstructions in the wall cavities

Use a smoke pencil to check for air leaks at SIP panel seams, especially along the ridge beam

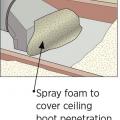

Use flashing tape to seal around any pipes or vents that penetrate through the foam

Utilities are commonly recessed into cutouts in the foam after concrete has been poured

Walls are being assembled at this SIP house

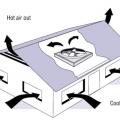

Whole house fans draw cool night-time air in through open windows and expel hot house air into the vented attic

Window and door rough openings in the ICF wall are surrounded with pressure-treated wood

Wrong - House wrap tape is not fully adhered at seam and flashing tape is missing from window head, jamb, and corner above window.

Wrong - Lack of a weather-resistant barrier allowed water to get behind the siding and rot the framing in this corner rim joist area.

Wrong - Nailing pattern on roof underlayment is erratic and excessive, house wrap should overlap seam, metal step flashing will need to be installed at roof-wall junction.

Wrong - No air barrier is present between the dropped ceiling/soffit and the attic.

Wrong - No air barrier is present between the dropped ceiling/soffit and the attic.

Wrong - No air barrier is present between the floor system and unconditioned space.

Wrong - No air barrier is present in the floor joists spanning over the garage and conditioned space of the home.

Wrong - Stucco has rotted and cracked above a window because of water damage due to lack of proper flashing and drainage.

Wrong - Tape is not well adhered to house wrap and wiring penetration is not sealed.

Wrong - The air barrier is not sealed (picture taken from garage looking into house).

Wrong - The band joist above this garage-house shared wall is not properly sealed.

Wrong - The caulk is too far from the sill plate to effectively air-seal the gap.

Wrong - The rigid foam that was installed as an air barrier at the rim joist was not properly air-sealed.

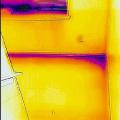

Wrong - This IR image is showing that cold air is entering the home at the window frame and the sill plate at the base of the wall.

Wrong - This IR image of a second-floor landing shows that attic air is flowing far into the interstitial floor cavity of the second-floor landing

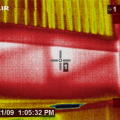

Wrong - This IR image shows where hot attic air has penetrated into the floor cavity that lies behind the stairwell wall

Wrong - Through-wall flashing has not been installed at brick wall intervals and house wrap is missing.

Wrong - Vinyl siding in incorrectly installed under not over door trim and door trim channel pieces are missing.

Wrong - Wall is missing step and kick-out flashing which has allowed water to rot the wood corner trim.

Wrong - Water has gotten behind the paint, possibly due to lack of window flashing, leading to blistering.

Wrong - Window sill trim was too tall for window frame and was poorly modified in an attempt to provide drainage out of the window.

Wrong – A visible gap in the insulated sheathing introduces unwanted outside air, creating a thermal bypass and encouraging convective air flow

Wrong – Cars should never be left running in a closed garage. Air seal walls, install a garage fan, and inform home owners of the dangers of running a vehicle with the garage door shut

Wrong – Compression and misalignment because insulation is not split around plumbing

Wrong – Compression and misalignment because insulation is not split around wires

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen

Wrong – Either this tape was not pressed down firmly or the surface was wet or dirty so the tape is not sticking properly even during construction.

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Fibrous insulation is not an air barrier and cannot be used to air-seal openings.

Wrong – Foam was sprayed at exterior sheathing and sill plate connection, leaving gaps beneath sill plate.

Wrong – Holes have been cut larger than needed, making them difficult to air-seal.

Wrong – If the insulated sheathing will serve as an air barrier and drainage plane, any cuts and seams must be taped or sealed.

Wrong – Insulation does not fill entire cavity nor is there an air barrier present between the double wall

Wrong – No air barrier installed between the walls and a larger gap between the walls that needs sealing

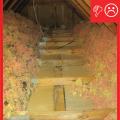

Wrong – No blocking installed to prevent attic insulation from falling into stairs and opening

Wrong – Roughly cut hole that is larger than the fan, making it difficult to seal

Wrong – Roughly cut hole that is larger than the fan, making it difficult to seal

Wrong – The backing on this knee wall was not air sealed prior to adding insulation.

Wrong – The batt insulation on this knee wall is not properly supported and there is no air sealed rigid backing to provide a solid air barrier.

Wrong – The blower door is installed improperly with a gap at the corner and along the side of the frame that will allow air leakage and could allow the frame apparatus to become dislodged during testing

Wrong – The blower door pressure reference hose (blue) ends too close to the outdoors side of the fan. Air moving across the end of the hose will affect the pressure reading

Wrong – The framing and wind baffle installation will not allow for required insulation depth.

Wrong – The rigid air barrier material between the cantilever and the conditioned space is not air sealed at the seams.

Wrong – There is no foam gasket or air-sealing between the sill plate and masonry foundation.

Wrong – There is visible light around the door because no weather stripping has been installed.

Wrong – These holes have been cut larger than needed, making them difficult to seal.

Wrong – These plumbing penetrations have been cut larger than needed, making them difficult to seal.

Wrong – This second-story floor plan has red lines that indicate openings from the attic into the interstitial floor space

Wrong – When insulated sheathing is installed correctly, you should not see daylight. Nail holes were also left unplugged.

Wrong – Whole house fan installed with holes in surrounding platform that need to be air sealed