Showing results 1 - 20 of 20

A blower door is installed in a doorway and is ready for testing

A home is tested at two points for enclosure air leakage

Calibrated blower door fans are used for envelope leakage testing

Floor cavity air pressure is measured by placing a tube into the floor cavity through a small drilled hole

Floor cavity pressure is measured by inserting a tube into the floor cavity using an extension pole

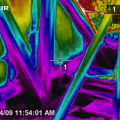

Infrared imaging shows cold conditioned air pouring out of the open floor cavities under this attic kneewall into the hot unconditioned attic

Infrared thermography during depressurization testing reveals air leakage at corner of spray foam-insulated room where wood-to-wood seams in framing were not air sealed

Limited attic access can make inspections for missing air barriers and insulation challenging

Limited attic access may make it necessary to use a bore scope when inspecting for missing air barriers and insulation in existing buildings.

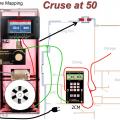

Pressure manometers are used to determine the level of pressurization and rate of leakage when conducting blower door testing and building diagnostics

Right - Manometers are placed away from the indoor side of the fan during blower door testing

Right – The blower door is installed snugly and securely to the door frame during testing

Right – The blower door pressure reference hose is placed well away from the outdoor side of the fan

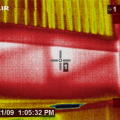

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Smoke generators are used to identify air leakage sites during depressurization testing

The air tightness of the garage-to-house air barrier can be tested with a blower door kit and two manometers

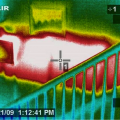

Wrong - This IR image of a second-floor landing shows that attic air is flowing far into the interstitial floor cavity of the second-floor landing

Wrong - This IR image shows where hot attic air has penetrated into the floor cavity that lies behind the stairwell wall

Wrong – The blower door is installed improperly with a gap at the corner and along the side of the frame that will allow air leakage and could allow the frame apparatus to become dislodged during testing

Wrong – The blower door pressure reference hose (blue) ends too close to the outdoors side of the fan. Air moving across the end of the hose will affect the pressure reading