Showing results 301 - 400 of 422

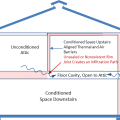

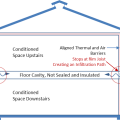

Thermal and air barriers at rim joist or new blocking prevent Infiltration of unconditioned air into the floor cavity

These ducts were installed within the home's conditioned space in a central chaise down the main hallway.

This “high static ducted cassette” heat pump system is similar to a traditional centrally ducted system, serving several areas of a home from one indoor unit

This Central Fan Integrated Supply (CFIS) duct is undersized and kinked, limiting required airflow This Central Fan Integrated Supply (CFIS) duct is undersized and kinked, limiting required airflow

This dropped soffit runs the length of the house providing a convenient place to locate one trunk duct with several very short side ducts that supply heat and cooling to most rooms of the house.

This ducted mini-split heat pump was installed in the unvented, conditioned attic and ducted with short duct runs to several nearby rooms.

This Habitat for Humanity builder ordered roof trusses with a 2-foot by 2-foot notch next to the center post then lined the cutout with rigid foam to form an insulated central duct chase to bring the heating and cooling ducts within the conditioned space.

This home’s ultra-efficient ground-source heat pump provides hot water for space heating as well as domestic hot water for the 50-gallon storage tank.

This single-zone mini-split ductless heat pump has only one indoor wall-mounted unit and one outdoor unit.

This traditional centrally ducted heat pump heats and cools the entire home through a network of ducts.

This typical dropped ceiling hallway chase shows a complicated air sealing scheme where chase ceiling drywall meets sidewall top plates

This utility room houses a high-efficiency gas boiler to provide hot water for the radiant floor heating system and faucets. It also has a central air source heat pump and an energy recovery ventilator.

To attach the flex duct to a main trunk duct or any other connection, the flex duct is pulled over the connecting collar at least 2 inches past the raised bead, then the insulation is pulled back

To keep chase width to a minimum, use flat sheet metal as opposed to a collar and flex duct for supplies into rooms where the chase is located

To measure air flow, a hole was made in this flex duct; a more accurate measurement could be taken if the duct material were rigid metal, not flex duct

To prepare for a total duct test at final, cover all of the supply outlets and return inlets

To prepare for a total duct test at rough-in, cover all of the supply outlets and return inlets

Transfer grills and jump ducts provide pathways for air to reach the centrally located HVAC return grille, even when bedroom doors are shut.

Trunk to duct connections are properly insulated and have been sealed with mastic

Two pieces of flex duct are spliced together with a metal sleeve, nylon draw bands, mastic, metal tape, and more mastic

Uninsulated, unsealed, or missing rim joists allow attic air and heat into the floor cavity

Unsealed, uninsulated rim joists allow outside air and heat into the floor cavity

Use masking tape as a removable sealer to stop air from leaking around the return grille filter.

Ventilation air inlets ≥ 2 ft. above grade or roof deck in Climate Zones 1-3 or ≥ 4 ft. above grade or roof deck in Climate Zones 4-8 and not obstructed

Ventilation air inlets located ≥10 ft. of stretched-string distance from known contamination sources such as stack, vent, exhaust hood, or vehicle exhaust

Ventilation inlet is not near any exhaust outlets/contamination sources and is at least 2 ft. above the roof deck

Ventilation inlet is too close to exhaust outlets and does not extend at least 2 ft. above the roof deck

Well sealed duct lifted into raised ceiling chase

When wrapping metal ducts with insulation allow two inches of overlap and staple along the seam with outward clinching staples

Wide saddle support provides sturdy support for the turn without pinching the flex duct

Wrong - Code requires a kitchen exhaust fan duct to be a smooth metal duct (galvanized steel, stainless steel, or copper) and to terminate outside, not in an attic or crawlspace.

Wrong - Duct seams were sealed with regular duct tape which has failed to hold; seams should have been sealed with mastic or approved metal tape.

Wrong - Flex duct insulation is overly compressed in 3 ways; Zip-tie fastener is over the insualtion not under the insulation at the duct boot collar, duct turning radius is too tight, and support strap is too tight.

Wrong - Flex duct resting on floor compressing insulation and causing condensation

Wrong - Flex ducts are prohibited by the IRC for kitchen exhaust and, at 28 feet, this duct is too long to be effective.

Wrong - If this kitchen exhaust duct had been extended a few inches, at least one bend could have been eliminated.

Wrong - Kitchen exhaust ducts are prohibited from terminating within 3 feet of an operable window or near gable vents.

Wrong - Kitchen exhaust fans must be located directly over the stove top to be effective at capturing and removing cooking pollutants.

Wrong - Metal tape is poorly adhered and metal duct and duct-to-subfloor seam is not sealed.

Wrong - Not enough straps were used to hang this flex duct so it is sagging, restricting air flow

Wrong - Penetrations in walls for ducts should be air sealed to reduce air leakage.

Wrong - The furnace intake and exhaust are too close to each other and are missing rodent screening.

Wrong - The furnace intake and exhaust are too close to each other and should be facing different directions.

Wrong - The IRC prohibits the use of flex duct for kitchen exhaust and only permits PVC duct for downdraft systems that meet specific exceptions; also, gaps at the ceiling have not been air sealed.

Wrong - The IRC requires that kitchen exhaust ducts terminate outside, at least 3 feet from operable windows.

Wrong - The seam around the duct boot where the duct boot enters the trunk duct has not been completely sealed with mesh tape and mastic.

Wrong - The support strap for the duct is too tight and the radius of the turn is too sharp.

Wrong - This is a poorly sealed chase with no solid air barriers along the sides of the chase and no caulk around the electrical wires installed through the ceiling of the chase.

Wrong - This kitchen exhaust duct uses flex duct, which is prohibited by code, and the duct’s 22-foot length and multiple bends will slow the movement of pollutants out of the home.

Wrong -The duct does not have enough support so it is sagging and compressing the duct

Wrong – A tear in the outer jacket of this duct shows where an in-line airflow measurement was made; the inner duct was not sealed and created a duct leak.

Wrong – Don’t use nails to fasten poly vapor barrier around flex ducts; it will allow moist air to reach the ducts where it could condense and ruin the insulation.

Wrong – Duct is pulling away from ceiling because it is not sealed to the ceiling

Wrong – Exhaust fan ducts must be smooth metal ducts; flex duct is not permitted by the IRC.

Wrong – Fiber board duct is not sealed at seams; flex duct is sealed with duct tape not mastic tape or UL-181 metal tape.

Wrong – Insulation should not be pinched where flex ducts connect to the trunk duct as compression of the insulation here can lead to cold spots and condensation on the duct surface.

Wrong – It is difficult to test the air flow in this fresh air intake duct due to poor access and inadequate length of straight duct to get an accurate in-line flow measurement.

Wrong – The duct for this kitchen exhaust fan is made of flex duct instead of smooth metal duct and the duct is not properly supported.

Wrong – the exhaust terminal for a clothes dryer should not be covered with a screen which could trap lint; instead, cover it with a hooded, louvered damper

Wrong – the interior seam of the branch duct to trunk duct juncture is sealed with mastic but there are gaps around the exterior seam that should also be sealed with mastic or metal tape.

Wrong – The kitchen exhaust fan duct is attached to flex duct, which is prohibited by code.