Showing results 1 - 84 of 84

A nylon draw band and tensioning tool are used to secure the inner coil of the pre-insulated flexible duct

A nylon draw band and tensioning tool are used to secure the inner liner of the pre-insulated flexible duct

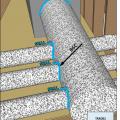

A second layer of rigid insulation is installed over the 2 in. by 4 in. retaining strip

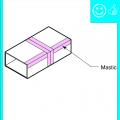

After securing the inner coil, cover the draw band and the seam with a generous amount of mastic

Air seal and insulate flex ducts

All other supply ducts and all return ducts in unconditioned space have insulation ≥ R-6

Because this ICF and spray foamed house is so well insulated, the HVAC system is smaller, the round metal ducts are smaller diameter, and the duct layout is more compact.

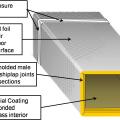

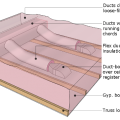

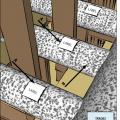

Buried ducts are laid on the floor of a vented attic then covered with spray foam and blown attic floor insulation

Collars that are specifically made for flexible duct have a raised bead to prevent the duct from slipping off

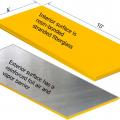

Cut fiber board with a red V-groove tool and a gray shiplap tool to create mitered corners and a shiplapped edge for duct sections

Cut-away view showing unsealed gaps around a heating duct that goes through a wall

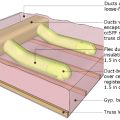

Ducts are insulated but strapping is compressing the insulation therefore reducing the R-value

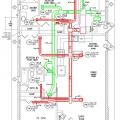

Example of an HVAC installer’s balancing report form

Hand tools for cutting fiber board sheets include a knife, straight edge, and color-coded edge-cutting tools

HVAC ducts can be encapsulated in 3 inches of closed-cell spray foam, then buried in R-49 of blown fiberglass insulation after the ceiling drywall is installed in the vented attic.

Install bottom layer of rigid insulation

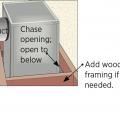

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

Prescriptive Path: Supply ducts in unconditioned attic have insulation ≥ R-8. Performance Path: Supply ducts in unconditioned attic have insulation ≥ R-6

Pull the insulation and outer liner of the flex duct over the collar to come in full contact with the liner and insulation of the trunk line or fitting and tape in place

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

Right - The rigid metal HVAC ducting is installed between the floor joists rather than in an unconditioned attic or crawl space to minimize heat loss.

Right – All supply ducts in this home were located in conditioned space; any return ducts that were located in the attic were insulated with closed-cell spray foam and buried in the blown-in attic insulation to prevent air leakage and heat loss.

Right – Batt insulation provides additional insulation for the home’s main duct chase.

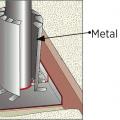

Right – Metal or fiberboard duct is mastic sealed at junction with duct register box

Right – Plastic tenting increases the height of the insulation above ducts that are located in the attic.

Right – R-25 of open-cell spray foam lines this new home’s attic ceiling, to protect HVAC ducts from heat and cold.

Right – Rigid foam is installed behind HVAC ducts to provide additional insulation to the ducts which are installed within the conditioned space.

Right- This flue pipe has been air sealed with sheet metal and fire-rated caulk and an insulation dam has been constructed to keep insulation from touching the hot flue pipe

Right: Ducts are completely buried beneath insulation to the depth specified in the plans

Right: ductwork is fully encapsulated with ccSPF prior to ceiling installation and burial

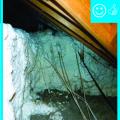

Right: Ductwork is installed in direct contact with lower truss cords. In this picture the main trunk is laying on the truss cords and branch ducts are temporarily held with strapping across truss cords. Ducts are well sealed with mastic

Seal all joints and seams in the metal ductwork with mastic before installing insulation

Seal seams in fiber board ducts with out-clinching staples, UL-181A-approved tape, and mastic

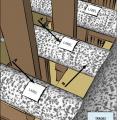

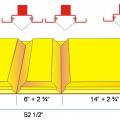

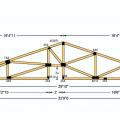

Specially designed roof trusses come with a two-foot by two-foot notch cut next to the center post providing space to install an insulated duct chase inside the home’s conditioned space but above the normal ceiling height.

Spray foam insulation used for raised ceiling duct chase

The attic duct chase insulated and sealed to the attic floor with spray foam

The attic is sealed and insulated along the underside of the roof deck with 5.5 inches of polyurethane spray foam, providing conditioned space for the HVAC system.

The inner liner of the flex duct is fastened to the collar with a tension tie, the connection is sealed with mastic, then the outer layer is pulled over and sealed with mastic or foil tape (Steven Winter Associates 2013).

The main trunk line of the ducts runs within an insulated duct chase installed in a notch designed into the roof trusses that runs the length of the home to provide supply air directly to most of the home’s ceiling registers.

The sealed, insulated crawlspace is a clean, dry location to house the main floor heating ducts and also provides bonus storage space.

The tape is covered with mastic to ensure an airtight seal between the duct and the fitting

This Habitat for Humanity builder ordered roof trusses with a 2-foot by 2-foot notch next to the center post then lined the cutout with rigid foam to form an insulated central duct chase to bring the heating and cooling ducts within the conditioned space.

To attach the flex duct to a main trunk duct or any other connection, the flex duct is pulled over the connecting collar at least 2 inches past the raised bead, then the insulation is pulled back

Trunk to duct connections are properly insulated and have been sealed with mastic

Two pieces of flex duct are spliced together with a metal sleeve, nylon draw bands, mastic, metal tape, and more mastic

When wrapping metal ducts with insulation allow two inches of overlap and staple along the seam with outward clinching staples

Wrong – Don’t use nails to fasten poly vapor barrier around flex ducts; it will allow moist air to reach the ducts where it could condense and ruin the insulation.

Wrong- A tie strap should not be used over the duct outer liner because it can compress the insulation. Tuck in the fibrous insulation and seal the outer liner to the connecting duct with mastic or foil tape (Steven Winter Associates 2013).

Wrong: Ducts are held above the ceiling plane with strapping to provide a good angle into top-entry boots. Once the ceiling insulation is added, this duct will protrude from the ceiling insulation and will not be buried

Wrong: Ducts are held from the rafters with strapping and a large beam prevents ducts from properly lying on the ceiling plane

Wrong: Ducts are not laid across the lower truss cords or ceiling, but are hung from the rafters by straps. As a result, ductwork is not buried

Wrong: Ductwork is not fully encapsulated with ccSPF insulation. The duct jacket is still fully visible at sections of the duct

Wrong: This exhaust fan duct is too long and terminates in the attic instead of going through the roof and it is improperly supported; it needs straps all along its length to prevent sagging.