Showing results 1 - 90 of 90

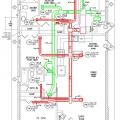

A duct leakage test is performed on a ducted heat pump system using a duct tester (blower fan) and a digital manometer.

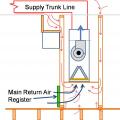

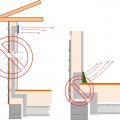

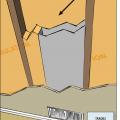

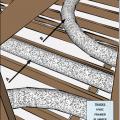

Air handler platforms used as return air plenums can draw air from vented attics and crawlspaces through other connected framing cavities

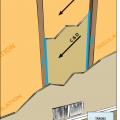

Bedrooms pressure-balanced and provide 1 sq. in. of free area opening per 1 CFM of supply air or achieve a Rater-measured pressure differential ≤ 3 Pa

Bedrooms pressure-balanced and provide 1 sq. in. of free area opening per 1 CFM of supply air or achieve a Rater-measured pressure differential ≤ 3 Pa

Building cavities not used as supply or return ducts unless they meet Items 3.2, 3.3, 4.1, and 4.2 of this Checklist

Cavity used for return is not insulated and is not air sealed, which will pull in air from outside

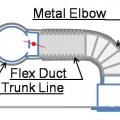

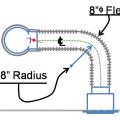

Consider using a metal duct elbow instead of flex duct at boot connections to prevent compressions

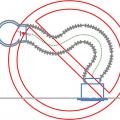

Coordinate with other trades including framers, plumbers, and electricians to prevent needless looping of flex duct

Door has been undercut to allow for specified amount of air flow therefore contributing to pressure balancing

Duct to boot connection of jump duct not fastened and sealed

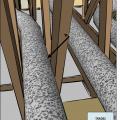

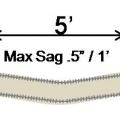

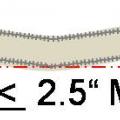

Ducts sagging because supports not installed at regular intervals

Example of an HVAC installer’s balancing report form

Fan housing was oriented in the correct direction to allow proper exhaust duct installation

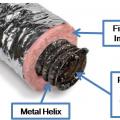

Flexible ducts in unconditioned space not installed in cavities smaller than outer duct diameter; in conditioned space not installed in cavities smaller than inner duct diameter

Flexible ducts supported at intervals as recommended by mfr. but at a distance ≤ 5 ft

HVAC ducts, cavities used as ducts, and combustion inlets and outlets may pass perpendicularly through exterior walls but shall not be run within exterior walls unless at least R-6 continuous insulation is provided on exterior side of the cavity

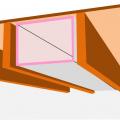

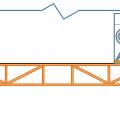

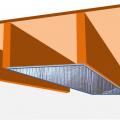

If a dropped soffit is used to house a duct, the soffit space must equal the duct diameter plus the insulation thickness

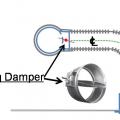

If airflow must be limited to a supply register, use balancing dampers at the trunk line rather than looping duct to control airflow

If HVAC duct must be installed in an exterior wall, separate it from the exterior with at least R-6 of continuous rigid insulation

Inadequate amount of insulation installed with compression, misalignment, and voids

Install bottom layer of rigid insulation

Install supply registers in floors or ceilings to avoid routing ducts through exterior walls

Install supports every 5 feet so that maximum allowable sag in flexible duct is no more than one-half inch per foot

Install supports every 5 feet so that maximum allowable sag in flexible duct is no more than one-half inch per foot

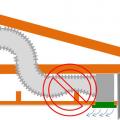

Lay out duct so that no radius of a bend or turn is less than the diameter of the airway

Open floor trusses used as return air plenums can draw air from any place connected to that floor

Pulling flex duct taut when installing greatly reduces the amount of friction caused by the ducting

R-6 flexible duct has 2 inches of insulation around the inner liner so a 12-inch duct requires a 16x16-inch chase

Right – Flex ducts are properly supported with straps that don’t pinch the insulation; closed-cell spray foam will be applied to the underside of the roof deck of this hot-humid climate home to provide an insulated attic space for the HVAC ducts.

Run-out ducts are installed over partition walls

Some builders create pan joists by attaching a solid sheet good to the bottom of a floor joist to create a return air pathway

Straps are spaced too far apart causing the straps to compress the duct under its own weight

The drywall above the dropped ceiling duct chase extends beyond adjoining top plates for a continuous air barrier

Well sealed duct lifted into raised ceiling chase

Wrong – Insulation should not be pinched where flex ducts connect to the trunk duct as compression of the insulation here can lead to cold spots and condensation on the duct surface.