Showing results 1 - 229 of 229

A constant airflow regulator is a modulating orifice that automatically regulates airflows in duct systems to constant levels

A constant airflow regulator is fitted into the neck of the supply duct to control air flow to deliver the design airflow regardless of pressure variations

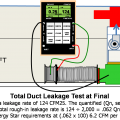

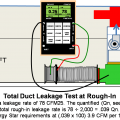

A duct leakage test is performed on a ducted heat pump system using a duct tester (blower fan) and a digital manometer.

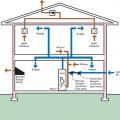

A ducted central return brings air from central return registers back to the air handler through insulated, air-sealed ducts

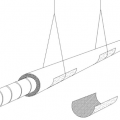

A nylon draw band and tensioning tool are used to secure the inner coil of the pre-insulated flexible duct

A nylon draw band and tensioning tool are used to secure the inner liner of the pre-insulated flexible duct

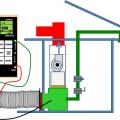

A technician assembles the spray sealant injection system to seal HVAC ducts from the inside

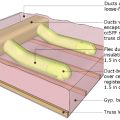

After securing the inner coil, cover the draw band and the seam with a generous amount of mastic

Air seal and insulate flex ducts

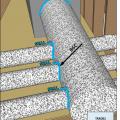

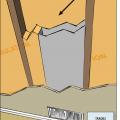

Air seal duct boot to ceiling by installing fiberglass mesh tape and mastic over seam

All other supply ducts and all return ducts in unconditioned space have insulation ≥ R-6

Back-draft damper still has a piece of tape that prevented it from rattling during shipping

Bedrooms pressure-balanced and provide 1 sq. in. of free area opening per 1 CFM of supply air or achieve a Rater-measured pressure differential ≤ 3 Pa

Bedrooms pressure-balanced and provide 1 sq. in. of free area opening per 1 CFM of supply air or achieve a Rater-measured pressure differential ≤ 3 Pa

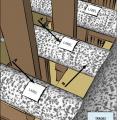

Building cavities not used as supply or return ducts unless they meet Items 3.2, 3.3, 4.1, and 4.2 of this Checklist

Cavity used for return is not insulated and is not air sealed, which will pull in air from outside

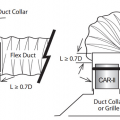

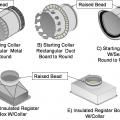

Collars that are specifically made for flexible duct have a raised bead to prevent the duct from slipping off

Connect the plastic application tunnel from the injection equipment to the supply plenum.

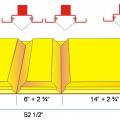

Cut fiber board with a red V-groove tool and a gray shiplap tool to create mitered corners and a shiplapped edge for duct sections

Door has been undercut to allow for specified amount of air flow therefore contributing to pressure balancing

Duct boot is air sealed to ceiling by covering the seam with fiberglass mesh tape and mastic

Duct boots sealed to floor, wall, or ceiling using caulk, foam, mastic tape, or mastic paste

Duct lacks adequate support to carry the weight so the few straps are pinching the duct

Duct to boot connection of jump duct not fastened and sealed

Ducts are insulated but strapping is compressing the insulation therefore reducing the R-value

Ducts sagging because supports not installed at regular intervals

Electronically controlled dampers allow this central air system to provide zoned heating and cooling to specific parts of the home.

Example of an HVAC installer’s balancing report form

Fan housing was oriented in the correct direction to allow proper exhaust duct installation

Fans from seperate dwellings exhausted together without back-draft dampers and not sealed

Fiberglass mesh tape is installed around a duct boot in preparation for air sealing with mastic

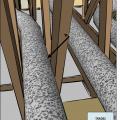

Flexible ducts in unconditioned space not installed in cavities smaller than outer duct diameter; in conditioned space not installed in cavities smaller than inner duct diameter

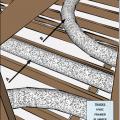

Flexible ducts supported at intervals as recommended by mfr. but at a distance ≤ 5 ft

Hand tools for cutting fiber board sheets include a knife, straight edge, and color-coded edge-cutting tools

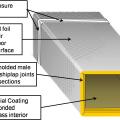

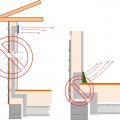

HVAC ducts, cavities used as ducts, and combustion inlets and outlets may pass perpendicularly through exterior walls but shall not be run within exterior walls unless at least R-6 continuous insulation is provided on exterior side of the cavity

If HVAC duct must be installed in an exterior wall, separate it from the exterior with at least R-6 of continuous rigid insulation

Inadequate amount of insulation installed with compression, misalignment, and voids

Install supply registers in floors or ceilings to avoid routing ducts through exterior walls

Manual D details show duct size and chase path

Packing tape has been removed and damper will be able to function properly once fan is installed

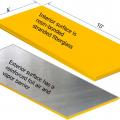

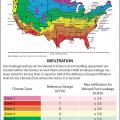

Prescriptive Path: Supply ducts in unconditioned attic have insulation ≥ R-8. Performance Path: Supply ducts in unconditioned attic have insulation ≥ R-6

Pull the insulation and outer liner of the flex duct over the collar to come in full contact with the liner and insulation of the trunk line or fitting and tape in place

Rater-measured duct leakage to outdoors ≤ 4 CFM25 per 100 sq. ft. of conditioned floor area

Right - All seams in the HVAC equipment and ductwork are sealed with mastic; because the HVAC equipment is in the garage, it is an air-sealed closet.

Right - An ultra-efficient (COP 5.7) ground source heat pump provides hot water to an air coil in the central air handler which uses a variable-speed electrically commutated fan motor to distribute conditioned air to the home’s ducts.

Right - Flex duct installed with adequate support and pulled taut to provide adequate air flow

Right - Flex duct installed with frequent supports, straight runs, and gradual turns to allow good air flow

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

Right - Straps are spaced close enough together to provide adequate support of the flex duct

Right - The HVAC ducts are located in conditioned space in a dropped hallway ceiling with very short duct runs for more efficient delivery.

Right - The precast insulated concrete walls of the basement provide a conditioned space for the high-efficiency (18 SEER, 9.5 HSPF) air-source heat pump, with its variable-speed fan, five-stage compressor, and MERV 11 filter.

Right – Flex ducts are properly supported with straps that don’t pinch the insulation; closed-cell spray foam will be applied to the underside of the roof deck of this hot-humid climate home to provide an insulated attic space for the HVAC ducts.

Right – Holes were drilled into the I joists between floors to run the small-diameter HRV ducts.

Right – R-25 of open-cell spray foam lines this new home’s attic ceiling, to protect HVAC ducts from heat and cold.

Right – Rigid foam is installed behind HVAC ducts to provide additional insulation to the ducts which are installed within the conditioned space.

Right – Transfer grilles, Jump ducts, and wall grilles provide passive returns for air returning from bedrooms to the central HVAC system

Right: A well-constructed air handler closet

Right: Air seal all seams in the return air plenum before installing a new air handler

Right: If existing straps are narrower than 1.5 inches, add sheet metal saddles to keep the duct from sagging and pinching

Right: Refrigerant piping is sealed where it exits the return plenum

Right: The bottom of the air handler cabinet is well sealed to the return platform

Right: The plenum liner is well sealed to the filter-backed grille

Right: Use mastic to air seal the return air plenum and to seal around refrigerant lines coming from the slab in the floor of the return

Seal all joints and seams in the metal ductwork with mastic before installing insulation

Seal seams in fiber board ducts with out-clinching staples, UL-181A-approved tape, and mastic

Seperate dwellings with their own seperate exhaust terminations

Straps are spaced too far apart causing the straps to compress the duct under its own weight

The AC unit has a drip pan and automatic shutoff in case the condensate drain gets clogged.

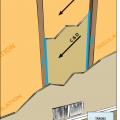

The drywall above the dropped ceiling duct chase extends beyond adjoining top plates for a continuous air barrier

The duct sealing spray injection system application tunnel inflates as the injection system operates

The duct sealing spray injection system includes a blower/heater (background) and the sealant injection unit (foreground)

The ducts are located in conditioned space in open-web joists between the floors and supported to prevent sagging.

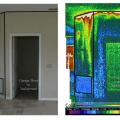

The grille in the photo on the left brings air into a return air plenum under an air handler platform. As shown in the infrared image on the right, the plenum is not air sealed so hot attic air is being pulled into the air handler closet.

The high-efficiency air-to-air heat pump is set in an overflow pan with an emergency shut off sensor in case the condensate tube were to clog and cause condensate to fill up the pan.

The tape is covered with mastic to ensure an airtight seal between the duct and the fitting

These ducts were installed within the home's conditioned space in a central chaise down the main hallway.

This “high static ducted cassette” heat pump system is similar to a traditional centrally ducted system, serving several areas of a home from one indoor unit

This dropped soffit runs the length of the house providing a convenient place to locate one trunk duct with several very short side ducts that supply heat and cooling to most rooms of the house.

This ducted mini-split heat pump was installed in the unvented, conditioned attic and ducted with short duct runs to several nearby rooms.

This home’s ultra-efficient ground-source heat pump provides hot water for space heating as well as domestic hot water for the 50-gallon storage tank.

This single-zone mini-split ductless heat pump has only one indoor wall-mounted unit and one outdoor unit.

This traditional centrally ducted heat pump heats and cools the entire home through a network of ducts.

This typical dropped ceiling hallway chase shows a complicated air sealing scheme where chase ceiling drywall meets sidewall top plates

This utility room houses a high-efficiency gas boiler to provide hot water for the radiant floor heating system and faucets. It also has a central air source heat pump and an energy recovery ventilator.

To attach the flex duct to a main trunk duct or any other connection, the flex duct is pulled over the connecting collar at least 2 inches past the raised bead, then the insulation is pulled back

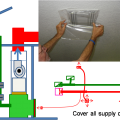

To prepare for a total duct test at final, cover all of the supply outlets and return inlets

To prepare for a total duct test at rough-in, cover all of the supply outlets and return inlets

Transfer grills and jump ducts provide pathways for air to reach the centrally located HVAC return grille, even when bedroom doors are shut.

Trunk to duct connections are properly insulated and have been sealed with mastic

Two pieces of flex duct are spliced together with a metal sleeve, nylon draw bands, mastic, metal tape, and more mastic

Ventilation air inlets ≥ 2 ft. above grade or roof deck in Climate Zones 1-3 or ≥ 4 ft. above grade or roof deck in Climate Zones 4-8 and not obstructed

Ventilation air inlets located ≥10 ft. of stretched-string distance from known contamination sources such as stack, vent, exhaust hood, or vehicle exhaust

Ventilation inlet is not near any exhaust outlets/contamination sources and is at least 2 ft. above the roof deck

Ventilation inlet is too close to exhaust outlets and does not extend at least 2 ft. above the roof deck

When wrapping metal ducts with insulation allow two inches of overlap and staple along the seam with outward clinching staples

Wide saddle support provides sturdy support for the turn without pinching the flex duct

Wrong - Duct seams were sealed with regular duct tape which has failed to hold; seams should have been sealed with mastic or approved metal tape.

Wrong - Flex duct insulation is overly compressed in 3 ways; Zip-tie fastener is over the insualtion not under the insulation at the duct boot collar, duct turning radius is too tight, and support strap is too tight.

Wrong - Flex duct resting on floor compressing insulation and causing condensation

Wrong - Metal tape is poorly adhered and metal duct and duct-to-subfloor seam is not sealed.

Wrong - Not enough straps were used to hang this flex duct so it is sagging, restricting air flow

Wrong - Penetrations in walls for ducts should be air sealed to reduce air leakage.

Wrong - The seam around the duct boot where the duct boot enters the trunk duct has not been completely sealed with mesh tape and mastic.

Wrong - The support strap for the duct is too tight and the radius of the turn is too sharp.

Wrong -The duct does not have enough support so it is sagging and compressing the duct

Wrong – Duct is pulling away from ceiling because it is not sealed to the ceiling

Wrong – These flex ducts are pulled taut, which is correct but they are inadequately supported with straps that are spaced too far apart and are too tight causing pinching of the insulation and turns are sharp rather than gradual.

Wrong – Two combustion appliances are sharing a flue which could lead to backdrafting if one appliance is updated to a direct vent appliance and disconnected from shared chimney.

Wrong- A tie strap should not be used over the duct outer liner because it can compress the insulation. Tuck in the fibrous insulation and seal the outer liner to the connecting duct with mastic or foil tape (Steven Winter Associates 2013).

Wrong: Open wall cavities in the un-air-sealed return plenum connect the plenum to attic spaces

Wrong: open wall cavity connected to this return air plenum is allowing cellulose attic insulation to be pulled into the furnace

Wrong: The door and filter were removed, allowing unfiltered air to enter the air handler leading to premature failure of the system due to dirt accumulation.

Wrong: The return plenum is not air sealed to separate it from the wall cavities and it should not be used for storage

Wrong: This return air plenum is not lined and air sealed

Wrong: This wall cavity is open to the attic allowing unconditioned, attic air to enter the HVAC system, bypassing the filter, and degrading system life and performance