Showing results 1 - 50 of 57

Between the ICF foundation walls, the builder sprayed closed-cell spray foam directly onto the gravel base to provide a vapor barrier and continuous layer of insulation under the slab.

Charis Homes built this custom for buyer home in the cold climate in North Canton, OH, and certified it to DOE Zero Energy Ready Home specifications in 2016.

Concrete is being poured into the wall forms made by the rigid foam insulated concrete form blocks.

Concrete is poured into the rigid foam shell of the insulated concrete form (ICF) walls; a plastic water barrier has already been installed to protect the below-grade wall surfaces.

Construct exterior walls with insulated concrete forms (ICFs) that provide insulation without thermal bridging, as well as air sealing, a drainage plane, and high structural strength.

Greenhill Contracting built this 4,190-ft2 house in Esopus, New York, to the performance criteria of the U.S. Department of Energy Zero Energy Ready Home (ZERH) program in 2016

Greenhill Contracting built this 4,454-ft2 home in the cold climate of Esopus, New York, to the performance criteria of the DOE Zero Energy Ready Home program in 2015.

Greenhill Contracting built this custom for buyer home in the cold climate in Newburgh, NY, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Greenhill Contracting built this production home in the cold climate in Esopus, NY, and certified it to DOE Zero Energy Ready Home specifications in 2014.

Habitat for Humanity South Sarasota County built this affordable home in the hot-humid climate in Nokomis, FL, and certified it to DOE Zero Energy Ready Home specifications in 2015.

ICF blocks used for the foundation walls consist of two sheets of rigid foam held together by plastic spacers and reinforced with steel bars forming a hollow wall that is filled with concrete for an ultra-efficient foundation system.

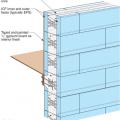

ICFs provide continuous wall insulation from the roof to the footing with very little thermal bridging

Insulated concrete forms are hollow foam blocks that are stacked to form walls, reinforced with plastic spacers and steel rebar, and then filled with concrete.

Manatee County Habitat for Humanity built this affordable home in the hot-humid climate in Bradenton, FL, and certified it to DOE Zero Energy Ready Home specifications in 2013.

Manatee County Habitat for Humanity trains its volunteers to construct homes made of construct insulated concrete forms (ICFs).

Reinforced concrete and rigid foam ICF walls can withstand disaster risks such as hurricanes, tornadoes, floods, wildfires, earthquakes, and pests.

Right - A dimpled-plastic geotextile mat covers the below-grade insulated concrete form (ICF) foundation to help keep water out of the foundation and to reduce hydrostatic pressure on the foundation during freeze-thaw cycles in winter.

Right – 11-inch ICFs provide R-50 of wall insulation from the footing to the roof on this cold-climate home.

Right – A paint-on flashing was applied to the window frames of this ICF house before installing the windows.

Right – A simple stacked rectangular design and well-insulated and air-sealed ICF walls provide for an extremely energy-efficient structure.

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – Insulated concrete form (ICF) blocks are stacked like bricks, then rebar is set horizontally and vertically in the plastic spacers, then concrete is poured; the rigid foam and spacers stay in place to add support and thermal resistance to the wall

Right – Insulated concrete forms (ICFs) provide the insulated stem wall for the slab-on-grade foundation for this SIP house.

Right – The entire first floor and second floor of these modular homes were assembled in the factory and installed on an insulated concrete basement foundation on site.

Right – The foundation of this ICF home was constructed of ICFs that were set in place on a gravel bed, then 3.5 inches (R-36) of closed-cell spray foam was sprayed directly onto the gravel, providing an effective air, vapor, and thermal barrier.

Right – The spacer structure of these ICFs provides supports for attaching the fasteners used to attach the metal studs of the below-grade walls.

Right – These three urban-infill cold-climate homes were built on insulated concrete foundations.

Right – This home was constructed with ICF blocks that extend from the footer to the roof line, providing consistent thermal resistance for the entire walls of the home

Right – Two inches of rigid foam was installed on the ground before pouring the basement floor slab while precast, pre-insulated concrete panels comprise the basement walls.

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

Seams in the ICF block are sealed so the EPS foam surface can serve as the drainage plane; no house wrap is needed.

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

The floor slab is completely insulated with ICF foundation walls and R-20 (3 inches) of closed-cell foam that is sprayed directly onto the ground before pouring the slab.

The foundation walls are ICF block providing two continuous layers (R-23) of insulation around the slab, which will sit on an additional 4 inches (R-20) of low-VOC EPS foam.

The Habitat affiliate makes its own “ICF” foundation walls with rigid foam held in place with wood spacers.

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

The ICF foundation wall of this home is covered with metal flashing before the siding is installed.

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

These ICF homes are blower door tested during construction, before the drywall is installed, when air leaks can be easily sealed.

This community of production homes in central New York state was built with insulated concrete forms (ICFs), which provide a highly insulated, airtight structure that is fire-, pest-, wind-, and earthquake-resistant.