Notes

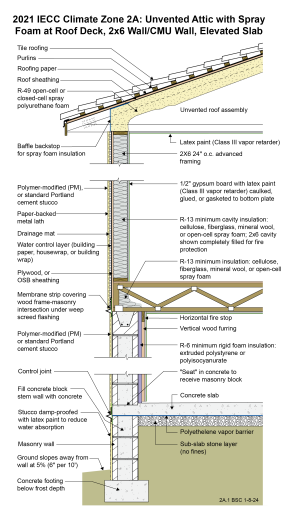

Drawing 2A.1: IECC CZ 2A: Unvented Attic with Spray Foam at Roof Deck, 2x6 Wall/CMU Wall, Elevated Slab

- The spray foam in the roof assembly can be either open-cell or closed-cell spray polyurethane foam. Closed-cell spray polyurethane foam significantly improves the wind uplift resistance of the roof assembly under hurricane conditions.

- If a raised-heel roof truss is used to allow R-38 attic insulation over the full width of the exterior wall, then R-38 can be used throughout the attic rather than R-49. See Section R402.2.1 of the 2021 IECC.

- A drainage mat is provided behind the stucco layer installed over the frame wall to control hydrostatic pressure. This assembly is drained to the exterior at a weep screed located at the bottom of the wood framing. It should not be drained into the CMU wall.

- The wood frame wall is framed with 2x6 24” o.c. advanced framing as it uses less board footage (volume of wood framing) than standard 2x4 16” o.c. framing and therefore is less expensive in material cost. It is also less expensive in labor (25% fewer framing members) and is faster to assemble. Although the code allows for 2x4 framing and lower R-value cavity insulation, the use of advanced framing and the associated cost savings more than offset the increase in the cost of cavity insulation (this of course depends on relative price fluctuations in labor and materials).

- Although the minimum R-value of the insulation in this wall is R-13 per IECC, fire code may require the entire cavity to be filled, likely resulting in a higher R-value for a 2x6 wall.

- Avoid vinyl wallpaper and oil-based paint or coatings in Climate Zone 2A. These wall coverings are vapor impermeable and increase the risk of condensation within the wall.

- The interior of the CMU wall is insulated with rigid insulation that also controls inward vapor drive out of the CMU mass wall. The thickness of the rigid insulation is typically selected to allow electrical boxes to be installed on the interior surface of the CMU mass wall without having to chisel the masonry blocks to seat the electrical boxes. Although only R-6 rigid foam insulation is needed on the interior of the CMU wall to meet energy efficiency code, thicker insulation may be needed to accommodate electrical outlets.

- The polyethylene vapor barrier under the concrete slab extends over the top of the CMU stem wall to act as a capillary break.

- Portions of the CMU wall may need to be filled solid to meet structural requirements or to accommodate anchor bolts for a sill plate.